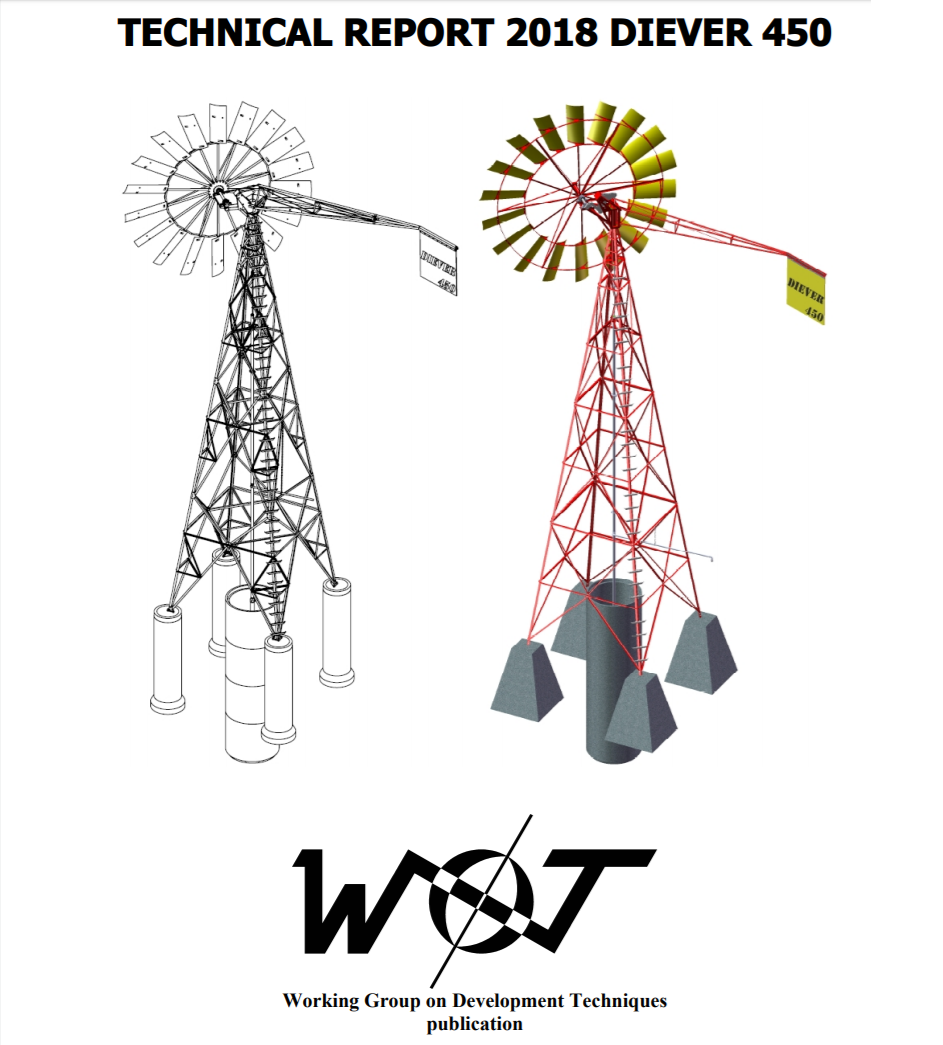

In light of the recent construction of a Diever windmill in South Africa, we have decided to publish a new Technical Report to describe recent developments and provide suggestions for further improvements. The TR2018 serves at once as a construction guide and as a comprehensive source of technical information on the Diever 450 windmill, supplementing the construction drawings.

The report can be obtained here.

The Technical Report 2018 was written by Chris Vos for the Working Group on Development Techniques (WOT), located in Enschede, The Netherlands. It replaces the Technical Report 1990 by Frans Brughuis which deals with an older version of the Diever 450.

Recent work done on the Diever prototype located on the WOT test terrain is described in the TR2018; this especially concerns the transmission and bearings. Many further improvements are suggested, including an improved rotor design, addition of counterweights to improve starting behaviour as well as more easily constructed foundation blocks. A completely new Diever design is also presented which completely consists of galvanised steel components.

Whoever wishes to start construction on their own Diever windmill is invited to contact the WOT to obtain construction drawings. The volunteers at WOT are more than willing to provide further advice where needed.

The Diever 450 is a water pumping windmill for use with deep wells in developing countries. The design has an Intermediate Technology character and use of advanced machinery is avoided. Main axle height is 10,5 meter and the mill is easily erected using a winch or tractor; when disassembled it can be transported on a Land Rover. Dievers have been built in a number of different countries, from Boliva to Nepal, and remain a reliable way of water supply all over the globe.