The Solar dryer

Historically the sun has been used to dry crops, especially around the equator. Many edible products and production crops like cacao and coffee beans have been dried on drying racks placed in the sun. The sun heats the produce and the surrounding air, this allows the water to evaporate. Drying the produce in open-air has some downsides though; Bugs and dust can land on the end product, and the produce can change color due to the direct sunlight.

To mitigate these problems it is possible to switch from drying racks to special solar dryers. Solar dryers can both dry produce in direct or indirect sunlight.

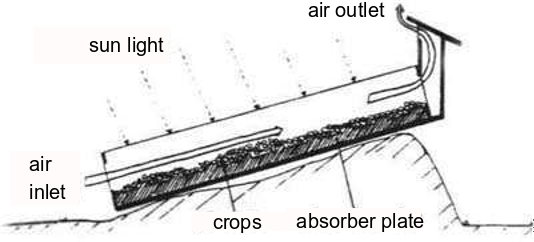

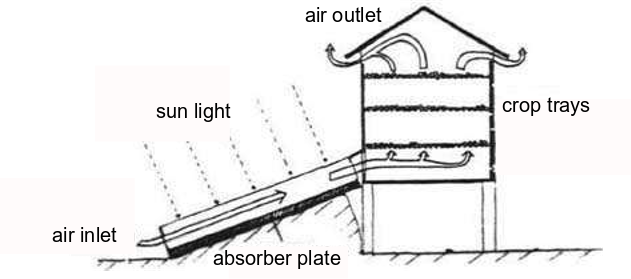

In the direct sunlight dryer type the light is directly hitting the crops, and in the indirect type the sunlight hits a dark surface heating the air which causes an airstream to develop which is guided through crop racks.

Both principles are explained below.

Literature:

Construction manual solar dryer

source: Home Power #57, February / March, 1997

Article on improving solar dryer

Source: Home Power #57, February / March, 1997

Direct solar dryers are cheap and easy to produce but provide little in the way of control over the drying temperature. Above all the fruit and vegetables change color when exposed to UV rays for a long time. This has more negative consequences, vitamin content reduces and the market value of a discolored crop is lower. When using an indirect solar crop dryer, the temperature can be controlled more accurately. Also since the produce is not exposed to direct sunlight and thus UV rays and the food does not change color, thus a higher market value.

The WOT used to have a solar dryer which is designed such that only 2 sheets of 4″x8″ are needed to make it, this making it a cost effective solution to dry food.