The WOT will host introduction activities every Wednesday and Thursday this September.

You can sign up for these activities using the following google form: Sign up via Google Forms

These activities will be organised like our weekly association nights (normally every Wednesday) so we’ll gather at the wot around 17:00 and have dinner at about 18:00, afterwards we would normally work on our projects and end the night around the campfire, but for this introduction period we have some activities planned.

-Wed 8 Sept,

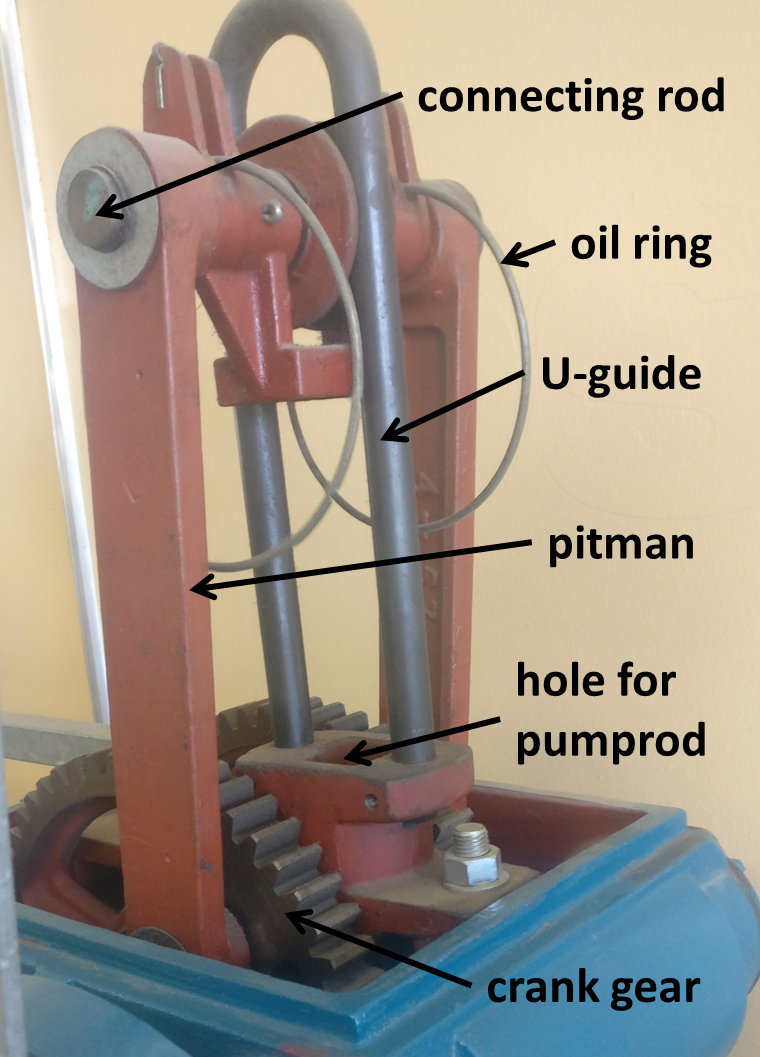

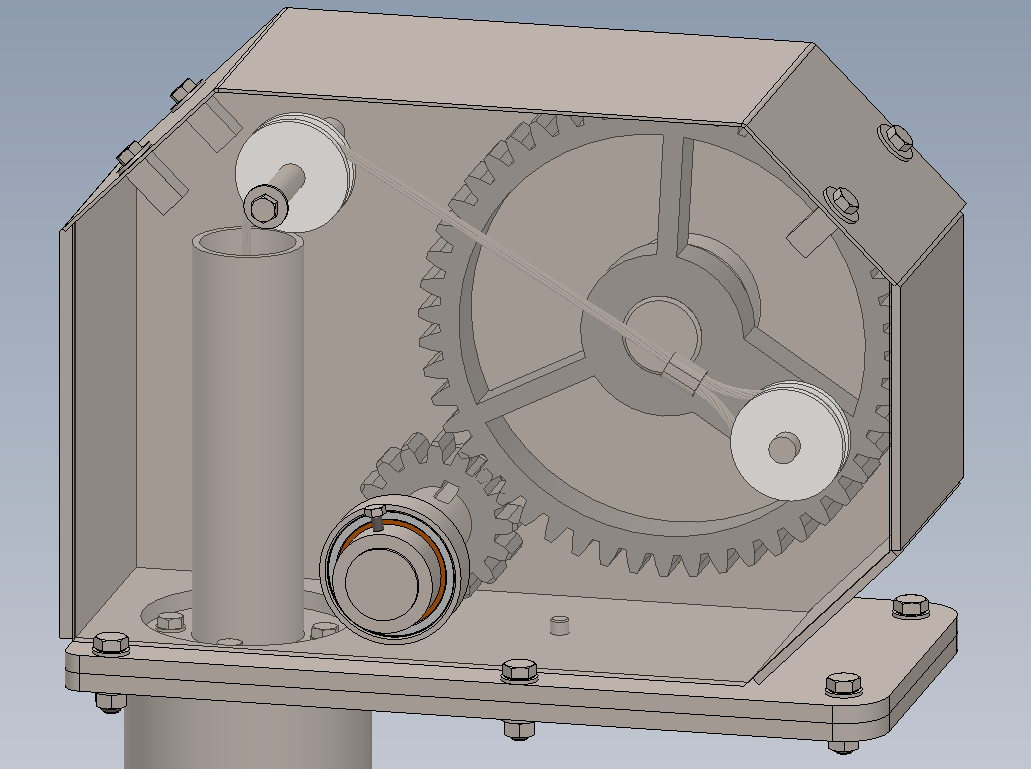

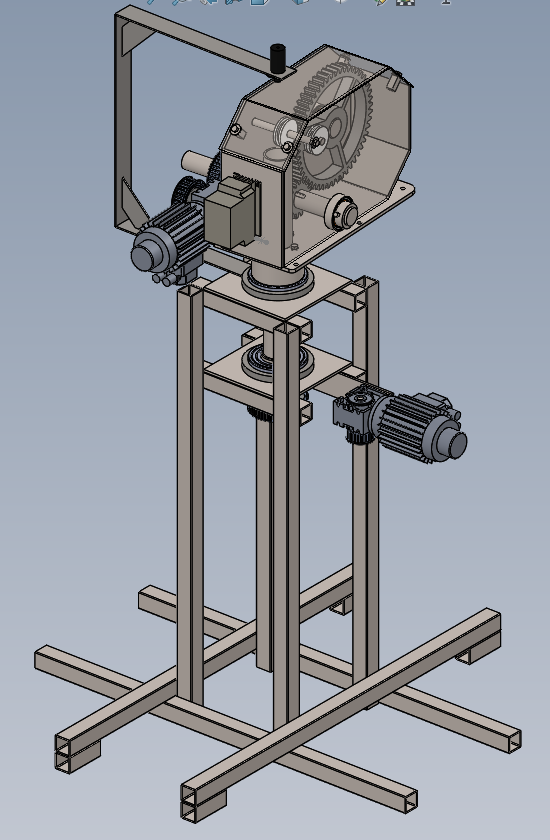

Introduction evening, we will give tours of our terrain and workshop and we will be making marble pumps

*A manual for the marble pump (you don’t need to prepare anything) can be found here.

-Thu 9 Sept,

We will host a lecture on well drilling (using manual methods that can be used in development countries), and of-course if you missed the tour on Wednesday there will be an option to be introduced to the terrain.

-Wed 15 Sept,

After the well drilling lecture of the previous week we will now actually drill a well using the “Mzuzu” or the “Emas” method.

*these methods will be introduced and explained in the lecture on Thu 9 Sept.

-Thu 16 Sept,

We will host a presentation on some of the wot’s most prominent projects from the past and discuss our various currently ongoing projects afterwards we will split up into groups and work on some small projects around the terrain.

-Wed 22 Sept,

We invited happy green islands to host a lecture on low-tech plastic recycling techniques.

Two people from happy green islands came to the wot and presented their work and goals, they showed us the website ekoMaluku and discussed technical innovations to localize plastic recycling (so it can be done on small islands).

-Thu 23 Sept,

We will divide the group into teams to play a pubquiz on mostly wot related topics (development techniques, climate, mechanical engineering etc.)

-Wed 29 Sept,

We will continue working on small projects and there will be the change to get involved/help out/watch over some larger projects.

-Thu 30 Sept,

We will be giving workshop courses to our new members to introduce them to and familiarize them with the various machines and tools in our workshop.

(Welding, grinding etc.)

On all these days we will be eating together at the wot, and ending the night around the campfire.

You can sign up for these activities using the following google form: Sign up via Google Forms

If you have any further questions please don’t hesitate to contact us.

Want to have a better overview of the wot from the comfort of your couch? watch this video that we made last year:

https://www.youtube.com/watch?v=EAGf125aG0I

*The dates and activities at the end of the video are outdated.